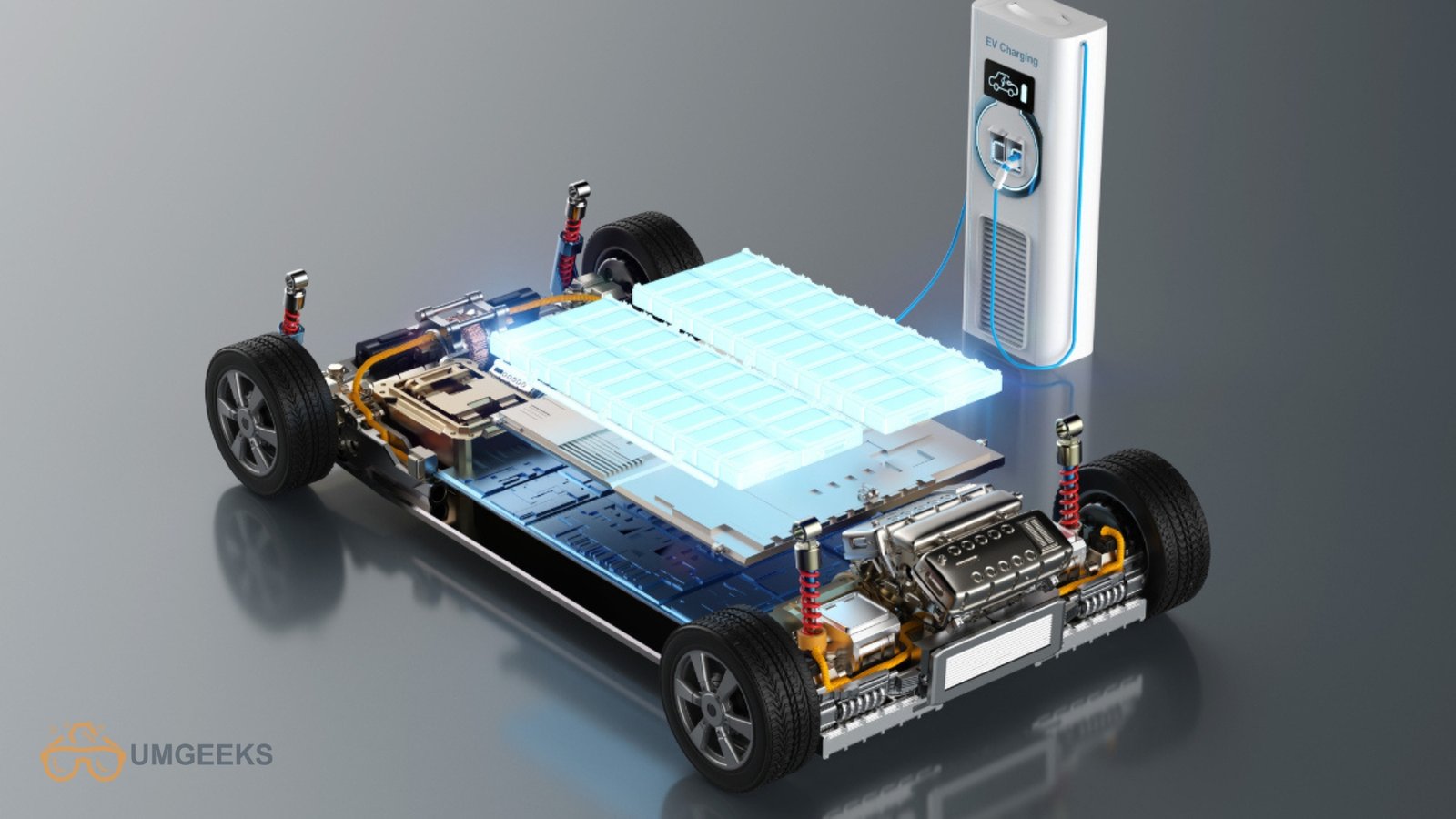

EV battery recycling technology has emerged as a crucial solution in today’s shift toward electric vehicles, raising a vital question: what becomes of these powerful batteries once they reach the end of their lifespan? This growing concern is fueling both innovation and urgency in developing more innovative recycling methods—an area quickly establishing itself as a pillar of sustainable mobility. With lithium-ion batteries containing a mix of hazardous substances and high-value metals, effective recycling not only prevents environmental degradation but also recovers essential materials needed to produce the next generation of batteries.

The Growing Need for EV Battery Recycling

In 2023, over 14 million electric cars were sold worldwide, marking a 35% increase from the previous year, according to the International Energy Agency (IEA). As EV adoption continues to surge, so does the volume of batteries nearing the end of their useful life. Most EV batteries last 8–15 years, depending on usage patterns and climate, meaning the first significant wave of retired batteries is already underway.

Without recycling, these batteries risk ending up in landfills, where they can leak toxic substances like cobalt, lithium, and nickel. Moreover, mining these metals from the Earth is energy-intensive, expensive, and environmentally damaging. Consequently, battery recycling isn’t just an environmental solution—it’s also economically sensible.

How EV Battery Recycling Works

There are three primary technologies for recycling EV batteries: pyrometallurgy, hydrometallurgy, and direct recycling. Each process has advantages and limitations, and ongoing research is aimed at optimizing their efficiency and scalability.

Pyrometallurgy (Smelting)

Pyrometallurgy involves high-temperature processing to recover metals from battery cells. The batteries are incinerated, and valuable metals like cobalt and nickel are extracted from the resulting slag. This method is already in use at an industrial scale due to its simplicity and ease of use. However, it often results in the loss of lithium and aluminum, and the energy consumption is notably high.

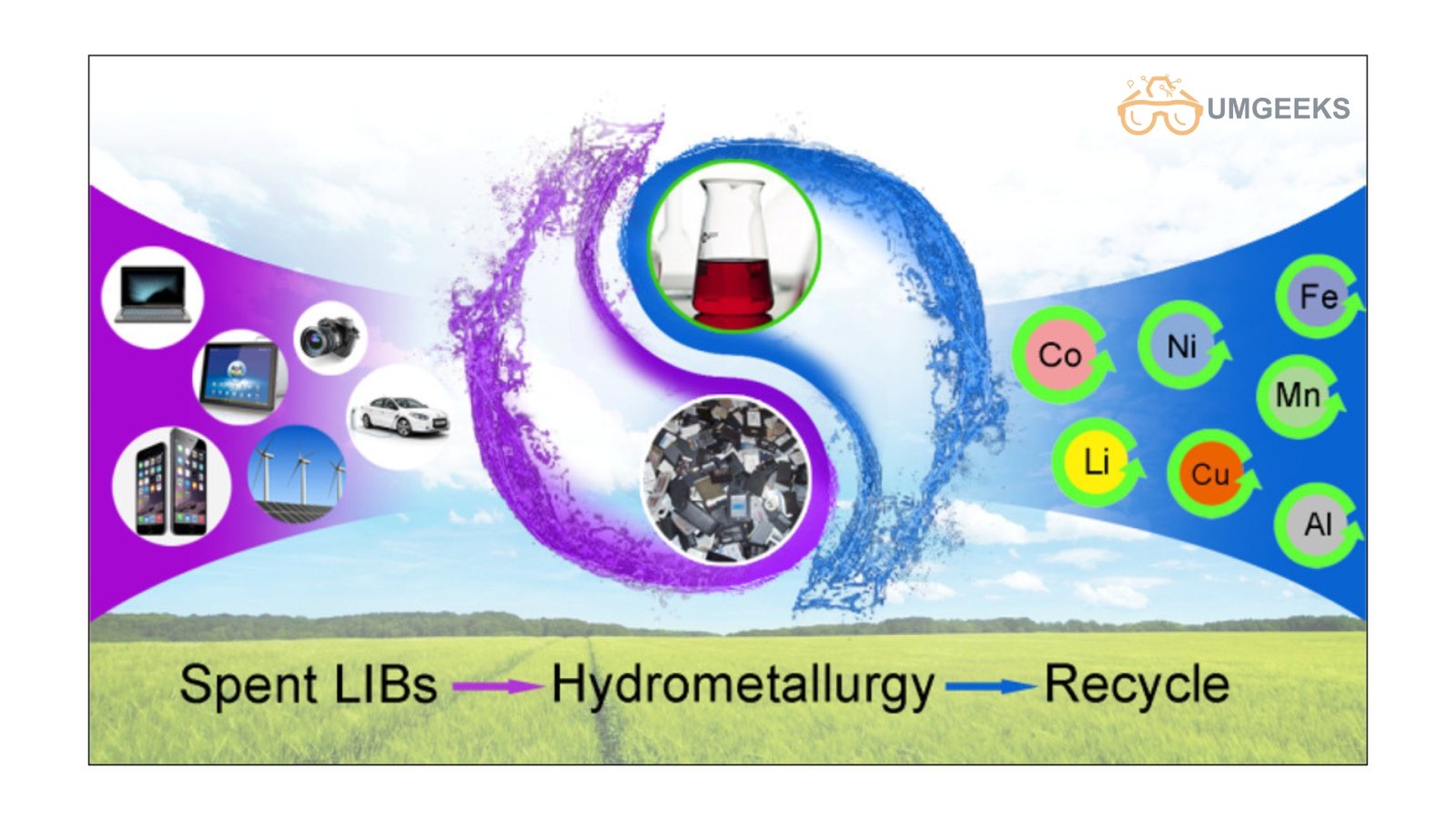

Hydrometallurgy (Leaching)

This method uses aqueous solutions, typically acids, to dissolve and separate metals. Hydrometallurgy enables the recovery of a broader range of metals, including lithium, and operates at much lower temperatures than smelting. The main challenge is the environmental impact of the chemicals used and the complexity of treating the resulting waste streams.

Direct Recycling (Closed-Loop Systems)

Direct recycling aims to recover and reuse the battery’s original materials without chemically breaking them down. For instance, the cathode material could be rejuvenated and reused in a new battery. This approach preserves the structural integrity of components and potentially reduces energy usage. However, it’s still in the experimental stage and not yet widely commercialized.

Advances in EV Battery Recycling Technology

Researchers and companies are investing heavily in new recycling technologies that improve yield, reduce waste, and operate sustainably. For example, Ascend Elements, a U.S.-based company, has developed a proprietary method to reclaim battery-grade cathode materials through a hybrid of hydro and direct recycling techniques.

Another innovation comes from Li-Cycle, a Canadian firm utilizing a “spoke and hub” model. Spokes located near collection centers mechanically process the batteries, and hubs perform hydrometallurgical processing to extract valuable elements. This decentralized model minimizes transportation costs and emissions.

Furthermore, companies like Redwood Materials, founded by former Tesla CTO JB Straubel, are building a circular supply chain where old batteries are collected, processed, and converted into new battery components domestically, reducing reliance on foreign sources.

Economic and Environmental Impact

Recycling batteries can recover up to 95% of valuable metals, significantly reducing the need for virgin mining. According to the World Economic Forum, recycling could supply 10% of the lithium, 25% of the cobalt, and 35% of the nickel required for new batteries by 2040. In turn, this would cut carbon emissions by more than 50% compared to primary production.

From an economic standpoint, recycled battery materials are becoming increasingly competitive in terms of price. As raw material costs rise due to global demand, recycling provides a cost-effective alternative for battery manufacturers. Moreover, governments worldwide are beginning to implement policies that encourage or mandate the recycling of batteries.

Government Regulations and Global Trends

The European Union leads the charge in battery recycling regulation. Under the EU Battery Regulation, manufacturers are required to collect and recycle used batteries, meeting strict recovery targets. Starting in 2025, EV batteries in the EU will be required to meet minimum recycled content thresholds.

Similarly, in China, automakers are legally required to recycle EV batteries. The Chinese Ministry of Industry and Information Technology has also developed a national traceability system to ensure proper disposal and resource recovery.

In the United States, although federal policy is still evolving, states like California are piloting extended producer responsibility programs. The Inflation Reduction Act (2022) includes incentives for using domestically sourced or recycled materials in EV batteries, further boosting the recycling sector.

Challenges Facing the Recycling Industry

Despite the progress, several barriers remain. First, battery design is not optimized for easy disassembly, making it both labor-intensive and hazardous to recycle manually. Second, the lack of standardized battery formats complicates the recycling process. Each EV manufacturer uses different chemistries and configurations, requiring customized recycling approaches.

Logistics and transportation of used batteries also pose safety and cost issues. Batteries are considered hazardous materials and require specialized handling, which limits the ease with which they can be collected and transported in bulk.

Finally, there’s the matter of economic viability. Until recently, the cost of extracting metals from recycled batteries was higher than mining virgin materials. However, as technology improves and regulations become stricter, this cost gap continues to narrow.

The Role of Second-Life Batteries

Before recycling, EV batteries often get a “second life” in less demanding applications. For example, retired EV batteries can be repurposed for energy storage in solar or wind farms. This second use can extend their life by several years before they are ultimately recycled. Companies like Nissan and BMW are already piloting such reuse programs in partnership with utility providers.

However, second-life applications must ensure battery safety, reliable performance, and standardization in integration with grid systems—an area still under development.

Future Outlook

Looking ahead, the EV battery recycling industry is poised for massive growth. According to BloombergNEF, the global battery recycling market is expected to surpass $18 billion by 2030. With innovations in automation, AI-based sorting, and eco-friendly chemical processing, the recycling process is expected to become safer, cheaper, and more efficient.

Governments, automakers, and tech companies must collaborate to design batteries with recycling in mind, enforce responsible recycling practices, and educate consumers on the importance of returning used batteries. Only a closed-loop battery supply chain can truly support the green promise of electric vehicles.

Frequently Asked Questions (FAQs)

1. Why is EV battery recycling technology important?

EV battery recycling is crucial in preventing environmental pollution, reducing the need for mining rare metals, and supporting the circular economy of battery production.

2. What materials are recovered from EV batteries?

Recycling can recover lithium, cobalt, nickel, copper, manganese, and aluminum, all of which are critical to producing new lithium-ion batteries.

3. Can EV batteries be reused before recycling?

Yes, batteries that still hold enough charge can be used in second-life applications such as energy storage systems before they are eventually recycled.

4. Are all EV batteries recyclable?

While most are recyclable, the effectiveness and economic viability of recycling depend on battery type, design, and the technology used.

5. What is the future of EV battery recycling technology?

The future involves automated, low-cost, and environmentally friendly recycling systems integrated with global supply chains and driven by strict regulations and consumer awareness.